The healthcare industry has seen tremendous advancements over the years, with innovations that enhance patient care and improve operational efficiency. Among these, the use of plastics has become pivotal, especially in hospital infrastructure. From lightweight, durable medical devices to robust furniture parts, plastics are revolutionizing the way hospitals are equipped and operated. This blog explores the role of plastics in healthcare, recent innovations, and the regulatory standards ensuring their safe use.

Overview of Healthcare Plastics:

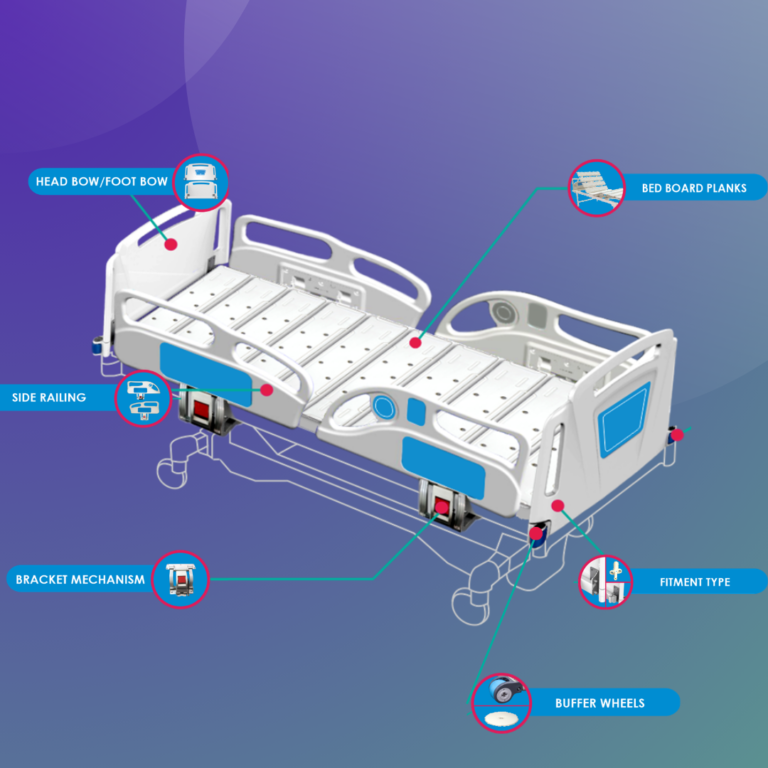

Plastics have become integral to the healthcare industry, particularly in hospital furniture and fixtures. Their versatility, durability, and cost-effectiveness make them ideal for creating a wide range of hospital infrastructure components. Common applications include plastic molded head bows, side rails, mattress platforms, and various accessories for hospital beds. These components not only enhance the aesthetic appeal of hospital environments but also contribute to the overall functionality and safety of medical facilities.

For example, the head/foot bow and side railings, often referred to as ABS panels, are lightweight yet strong, making them easy to assemble and disassemble. This feature is crucial in hospital settings, where efficiency and hygiene are paramount. Additionally, plastic components such as over-bed tabletops, bedside locker parts, and spine boards offer a pleasing finish and can be customized to match the hospital’s decor and color scheme.

Recent Innovations in Hospital Infrastructure:

Innovations in plastics for hospital infrastructure have led to significant advancements in the design and functionality of hospital equipment. Companies like Mitsu have been at the forefront of these developments, consistently delivering high-quality, ergonomically designed hospital furniture parts that meet international standards.

One of the notable innovations of Mitsu is the M4 patent, which pertains to plastic components used in ICU beds. These components are designed for beds, offering superior functionality and aesthetic appeal. The side rails, for instance, feature a curved finish that complements the arch of the headbow and footbow, enhancing the overall look of the bed. An angle indicator on the side rail helps healthcare providers accurately position the bed, which is especially important in motorized beds.

Mitsu has also introduced a variety of accessories that improve the usability of hospital beds. These include plastic rod mounts that replace traditional metal ones, offering a non-corrosive, easy-to-use alternative. Additionally, shock-absorbing wheels and mounting rails provide enhanced mobility and stability, making them essential for hospital beds that need to be frequently moved or adjusted.

Mitsu’s commitment to innovation is further exemplified by their development of custom molding services. These services allow hospitals to tailor their equipment to specific needs, ensuring that every piece of furniture or fixture is optimized for patient care. This customization not only meets functional requirements but also aligns with the hospital’s aesthetic preferences, creating a more comfortable and visually pleasing environment for patients and staff alike.

Regulatory Requirements for Healthcare Plastics:

The use of plastics in healthcare is governed by stringent regulatory standards to ensure safety, durability, and biocompatibility. These regulations cover various aspects, including material selection, design, manufacturing processes, and final product testing. In the case of hospital infrastructure, plastics must be robust, ergonomic, and aesthetically pleasing while meeting the rigorous demands of a healthcare environment.

Plastics used in hospital infrastructure must also adhere to economic considerations, providing cost-effective solutions without compromising quality. Mitsu, for instance, has aligned its products with these regulatory requirements by developing a range of hospital furniture parts that not only meet the necessary safety standards but also offer excellent value for money.

Mitsu’s Contribution to Healthcare Plastics:

Mitsu has emerged as a leader in the plastic molded furniture space in India, pioneering the development of high-end, innovative products that cater to the healthcare industry. Their products serve as convenient import substitutes, supporting the ‘Made in India’ campaign and contributing to the nation’s goal of becoming a global manufacturing hub.

The company’s continuous innovation policy ensures that they stay ahead of the curve, consistently introducing new products that meet the evolving needs of the healthcare industry. By maintaining close communication with Original Equipment Manufacturers (OEMs), Mitsu ensures that their products are not only innovative but also practical and aligned with the latest market trends. Mitsu has been awarded consistently as Top 100 SME since 2014 and have added numerous awards and accolades including Best Innovation ET Polymers award since last 4 years.

Conclusion:

Plastics have become indispensable in the healthcare industry, particularly in hospital infrastructure. Companies like Mitsu are leading the charge, offering a wide range of plastic components that enhance the functionality, aesthetics, and safety of hospital environments. As the industry evolves, the role of plastics in healthcare is set to become even more significant, driving further advancements in hospital infrastructure.